Dissecting a Battery: 21 Years of Technological Secrets Hidden in Lithium-Manganese Button Cells

In the quiet laboratory of Power Glory in Yichang, a lithium manganese button cell battery with a diameter of no more than 20 millimeters rests quietly on the experimental table. When professional tools carefully pry open its outer shell, what is revealed is not only the layered material structure, but also a 21-year history of technological evolution.

In today's world, lithium manganese button batteries, with their stable performance and portability, have become an indispensable power source for small electronic devices. From smartwatches to electronic scales, from medical devices to IoT sensors, behind these seemingly ordinary batteries lies more than two decades of accumulated and breakthrough technological processes.

Within the outer shell, the universe begins to unfold.

As the casing of the lithium manganese button cell is slowly opened, its internal structure is revealed in an orderly fashion. Negative electrode shell, lithium sheet, separator, positive electrode sheet, electrolyte, positive electrode cap—each of these seemingly simple components embodies years of technological accumulation.

Commonly used button cell battery models include CR2032 and CR2025, where "C" represents the button cell system and "R" indicates a circular battery shape. The numbers implicitly reveal the battery's dimensions: the first two digits represent the diameter (in mm), and the last two digits represent the thickness (in 0.1 mm units).

For example, the CR2032 has a diameter of approximately 20 mm and a thickness of approximately 3.2 mm. This limited space dictates extremely high precision requirements for each component.

The positive electrode shell is larger, while the negative electrode shell is smaller and has a mesh structure on its surface. This differentiated design is not arbitrary but the result of years of consideration for safety and performance stability.

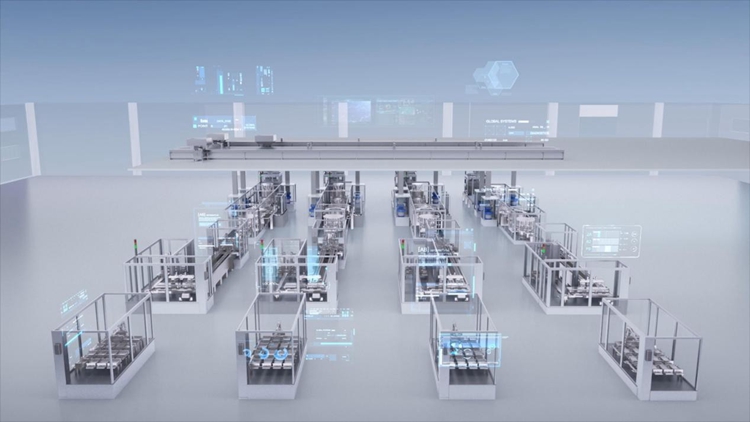

Intelligent production control, technological breakthrough

Fully enclosed powder granulation equipment, fully automated batching, and fully automated transfer overcome the limitations of traditional cathode processes that cannot be replaced by manual labor.

By moving the dehydration process from the cathode sheet stage to the powder stage, argon positive pressure storage ensures powder moisture content is ≤200ppm, reducing sheet quality fluctuations by 50% compared to traditional processes, completely eliminating the "humidity sensitivity" problem.

A unique cathode formula achieves liquid absorption in 10 seconds (traditional processes require 30 minutes). Cathodes fully saturated with electrolyte have an average moisture content reduction of 42% (calculated at the upper limit of control), and batch-to-batch consistency is improved, effectively rendering vacuum soaking processes obsolete.

A 24-punch rotary sealing machine: sealing speed of 200pcs/min (industry average 80pcs), reducing punch volume by 67%, eliminating electrolyte splashing, and achieving coaxiality deviation ≤0.01mm, redefining the limits of sealing precision.

AI-powered visual inspection: Online weighing/flow meter/CCD triple quality control ensures 100% inspection of key parameters; deep learning algorithms identify over 20 types of appearance defects with micron-level accuracy; zero missed detections and zero false positives result in automatic sorting of defective products, creating a rock-solid quality defense line.

These innovations not only improve product consistency but also effectively reduce energy consumption, aligning with the green and low-carbon development trend of modern manufacturing.

Wide temperature range, pushing the limits

With the diversification of electronic product usage environments, lithium-manganese button batteries also need to withstand more demanding temperature conditions. The successful development of wide-temperature lithium-manganese batteries is further proof of technological advancements.

Batteries produced by Power Glory can maintain capacity even in both low and high temperature environments, greatly expanding the application areas of lithium-manganese button batteries. Omnergy's lithium-manganese button batteries possess excellent wide-temperature characteristics. This means that the battery can maintain stable capacity output even in low or high temperature environments, significantly expanding its application range.

This wide-temperature performance makes this battery particularly suitable for automotive tire pressure gauges. Although small in size, its technological content is not to be underestimated. It solves the long-standing problem of wide temperature range requirements for tire pressure monitoring systems, capable of handling extreme operating environments from -40℃ to 125℃, while also withstanding the significant vibrations and centrifugal forces generated by high-speed tire rotation.

This product breaks the foreign technology monopoly, and orders have been overwhelming since its launch. Rigorous testing by leading customers has also confirmed its performance advantages.

The road ahead: Innovation never stops

Power Glory's technological evolution in lithium-manganese button cells has never ceased. With the continuous emergence of new materials, battery performance is constantly improving.

Twenty-one years is enough for an infant to grow into an adult, and enough for a technology to mature from its nascent stage. Each seemingly simple lithium-manganese button cell produced by Power Glory embodies the accumulation of meticulous technological evolution.

From material ratios to structural design, from manufacturing processes to safety protection, the secrets hidden within lithium-manganese button cells not only record past wisdom but also quietly outline the blueprint for future green energy.