Say goodbye to leakage risks: How do lithium manganese batteries protect precision equipment with their superior structure?

A leaking battery can instantly render a device worth of expensive equipment, but the innovative design of lithium-manganese batteries is becoming the terminator of this problem. It's common to discover, upon opening long-abandoned electronic devices, that leaking batteries have damaged internal components. Battery leakage not only damages equipment but can also lead to the loss of critical data, resulting in incalculable losses. While other batteries are prone to leakage under high temperatures, over-discharge, or long-term storage conditions, lithium-manganese batteries, with their innovative internal structure and multiple safety protections, are quietly changing this landscape, becoming the "guardian" of precision equipment.

Why is the pain of leakage so hard to avoid?

Battery leakage is a common nightmare for many people. One user on a forum shared their painful experience: "My popular smartwatch battery leaked. I cleaned it several times, but the resistance setting still won't return to normal. Leakage is terrifying... Once, a timer socket leaked, and the entire circuit board was ruined."

How many people can relate to this experience? Battery leakage not only damages the battery itself, but can also render expensive electronic devices unusable. This is especially true for devices that require continuous power, such as multimeters, remote controls, and smoke detectors, where battery leakage poses a serious threat. These devices are often left unattended after installation, and once battery leakage occurs, the damage is often irreversible.

Lithium-manganese batteries: Structural innovation eliminates the risk of leakage.

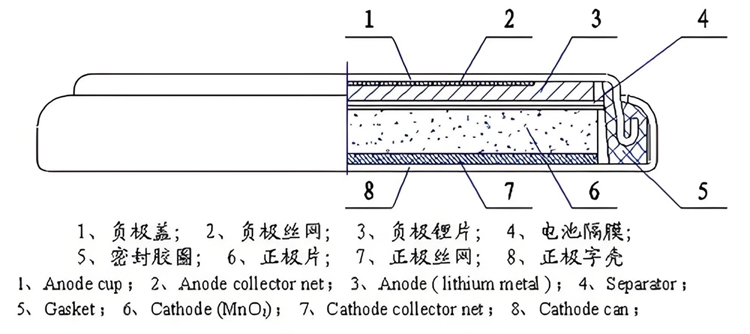

Compared to traditional batteries, lithium-manganese batteries have undergone revolutionary structural design improvements, eliminating the possibility of leakage at the source. The innovation of high-capacity, leak-proof lithium-manganese button batteries lies in the inclusion of a ring-shaped support frame inside the positive electrode casing, with evenly distributed flow holes on the frame walls. This ring-shaped support frame, together with the inner wall of the positive electrode casing, forms a ring-shaped electrolyte chamber, effectively controlling electrolyte flow and significantly reducing electrolyte leakage inside the battery.

Multiple protections provide comprehensive safeguards for battery safety.

In addition to leak-proof design, lithium-manganese batteries possess multiple safety protection mechanisms, forming a robust safety barrier. The multi-layered explosion-proof lithium-manganese battery employs a structure with a protective cavity between a welded outer and inner shell, isolating the battery from the external environment and reducing external pressure. Even in abnormal situations where internal pressure suddenly increases, the annular support frame can withstand the pressure deformation first, buffering the pressure and protecting the battery, thus greatly improving battery safety.

Ideal choice for precision equipment

The stable voltage and leak-proof characteristics of lithium-manganese batteries make them an ideal power source for precision electronic devices.

A battery enthusiast shared, "I generally prefer Li/MnO2 batteries; if used lightly, one can last for many years, and I don't have to worry about leakage."

Lithium-manganese batteries have an open-circuit voltage of approximately 3V, and their stable discharge voltage is a major characteristic. This stable discharge characteristic, combined with their leak-proof design, makes lithium-manganese batteries particularly suitable for applications requiring stable, long-term power supply, such as computer motherboards, mobile communication devices, and electronic memory systems.

For devices that require long-term power supply, such as smoke detectors, lithium manganese battery packs can work continuously for up to ten years, completely eliminating the hassle of frequent battery replacements for users.

Power Glory's products offer safer and more reliable battery technology.

With the continuous development of technology, the production process of Power Glory's lithium manganese batteries is also being continuously improved, further enhancing their safety and reliability.

The assembly line employs advanced sealing technology, which plays a crucial role in preventing battery leakage and extending shelf life. Laser cutting technology improves the processing precision of the negative lithium electrode sheet, further optimizing the battery's sealing performance…

Every rigorous production process ensures that each lithium-manganese battery leaving the factory has a high degree of consistency and reliability, allowing consumers to use it with confidence.

From expensive professional instruments to everyday smoke detectors, from children's electronic toys to critical medical equipment, Power Glory Technology's lithium manganese batteries are silently protecting our precision equipment.

Power Glory's batteries feature a circular support frame, a precision sealing structure, and an explosion-proof design, forming multiple safety barriers that make the risk of leakage a thing of the past.

Power Glory understands that the significance of technology lies not in showing off, but in solving the pain points that plague users. Choosing power glory means choosing a reliable guarantee for your equipment.