Why omnergy Lithium-Manganese-Dioxide Batteries Can Meet the Requirements of Stringent Certification?

2025 marks a critical turning point for the medical device industry. The implementation of a series of new regulations is profoundly changing the certification requirements for power supply components. The International Electrotechnical Commission (IEC) has also updated its safety testing standards for lithium coin-cell batteries. These changes together form the new regulatory framework for medical device power supplies in 2025.

As a critical power source for numerous medical devices, primary lithium-manganese button batteries face unprecedented compliance challenges.

Facing the stringent standards for medical battery products, Power Glory conducts comprehensive testing from the material to the energy source, utilizing medical-grade battery materials. Fully enclosed powder granulation equipment, fully automated batching, and fully automated transfer overcome the limitations of traditional manual cathode production. 100% intelligent testing ensures medical battery failure prevention. Furthermore, Power Glory has passed the medical device industry quality management system certification, as well as UL and IEC safety certifications, ensuring safety, stability, and reliability, unlocking the endless possibilities of lithium batteries and smart life.

Background and expansion of the new regulations

This means that medical devices using lithium-manganese button batteries, whether professional large-scale equipment or portable home devices, need to meet unified and strict standards.

The expansion of regulatory scope reflects the development trend of the medical device market: more and more medical devices are moving from hospitals to homes and from fixed use to portable use. This shift places higher demands on power supply safety.

Changes in key technical requirements

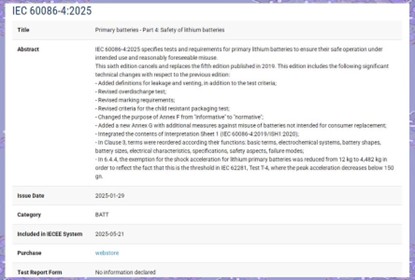

IEC 60086-4:2025, a key standard for button-type lithium battery safety testing, has undergone a series of major technical revisions. The new version includes revisions to over-discharge testing, labeling requirements, and child-resistant packaging testing.

These changes directly affect the design and production process of lithium-manganese button batteries. For example, the standard adds the definition of leakage and ventilation to the test basis, which means that the battery sealing performance will become a key indicator for safety assessment.

For lithium-manganese button batteries, a key challenge is preventing accidental charging. Because lithium primary batteries are not designed to be charged, battery manufacturers need to specify the maximum abnormal charging current limit.

The new regulations also strengthen the safety requirements for battery enclosures. Battery compartments in medical devices need to provide proper ventilation to prevent gas accumulation that could lead to ignition or explosion risks.

At the same time, the design of the battery compartment must be able to avoid accidental short circuits of the battery, which requires that the isolation between the positive and negative contacts of the battery must meet safety standards.

Technical advantages of omnergy lithium manganese button battery

Power Glory's primary lithium-manganese button batteries are ideal power sources for medical equipment due to their high energy density, stable discharge characteristics and wide temperature operating range.

Unlike conventional consumer batteries, batteries for medical devices must meet more stringent performance requirements. The lithium-manganese chemistry offers high open-circuit voltage and low self-discharge, ensuring reliable operation of medical devices even after long-term storage.

In terms of safety, the lithium-manganese button battery produced by Power Glory adopts a sealed structure design to effectively prevent electrolyte leakage and meet the strict definition of leakage in the new standard.

In response to the over-discharge test and impact test required by the new regulations, the lithium-manganese button battery produced by Power Glory has demonstrated excellent mechanical safety and electrical safety performance by optimizing the internal structure and electrolyte formula.

Technical measures to meet certification requirements

To meet the new regulations for 2025, primary lithium-manganese button batteries have undergone multiple upgrades in production processes and testing standards.

In terms of material selection, we use high-purity raw materials and separator materials to ensure the stability of the battery in high temperature and high humidity environments. At the same time, we strictly control the content of heavy metals to meet the restrictions on hazardous substances in medical devices.

In terms of production technology, we use dry liquid injection + rotary sealing to increase the electrolyte utilization rate by 9%, saving 15 tons of electrolyte annually, making the best use of every gram of resources.

In terms of quality, Power Glory has an overwhelming advantage in consistency: automotive-grade quality control: key characteristic CPK≥1.67; capacity standard deviation: CR2032 batch σ value ≤2mAh (international competitors ≤5mAh), MAD ≥240mAh. We have redefined the industry baseline.

Practical applications and cases

In applications such as pacemakers, hearing aids, and portable medical monitoring devices, Power Glory's primary lithium-manganese button batteries have demonstrated excellent performance.

A certain type of implantable medical device, using our lithium-manganese button cell batteries, performed well in an 85°C high-temperature storage test, with no leakage or performance degradation. This demonstrates the battery's reliability in extreme environments.

In terms of electromagnetic compatibility, our battery and shielding design helped an in vitro diagnostic device manufacturer easily pass the rigorous testing of IEC standards.

Future Trends and Outlook

Power Glory's focus on battery design is based on safety considerations. Through innovative structural design, the lithium-manganese button battery achieves high power output while meeting the stringent safety requirements of medical applications.

Intelligent safety monitoring will become the future of power supplies for medical devices. With the advancement of cutting-edge artificial intelligence medical devices, the requirements for supporting power supplies will also become more specialized. Lithium-manganese button batteries have continuously proven their safety and reliability, securing a niche in the medical device market.

Power Glory demonstrated that through innovative structural design, medical-grade material selection and strict quality control, lithium-manganese button batteries can meet these requirements. Standard updates are not the end, but a new starting point for the coordinated progress of safety and technology.